Case-packing and Palletizing System Consulting

Our End-of-Line Engineers work for you to develop the single-best solution. Why?

- You may have limited staff or resources - you have product to get out the door!

- You wish to remain anonymous to the field of robotic end-of-line system vendors.

- Accelerate / Expedite a robotic bag palletizer project timeline.

- Develop a long-term, phased-in, modular approach to robotic bag palletizing.

- Get an objective view - we represent no robot manufacturers and only work for only the client!

- You already have the palletizer - you just need to increase rate, add products, modify end-of-arm-tooling, or enhance reliability.

- Compare / contrast various types of robotic bag palletizers and systems.

- Compare / contrast various robotic bag palletizer brands.

- Customize the service to include as much or as little as you need.

- You own the defined robotic bag palletizer solution(s) and layout(s) and can go out for bid easily.

- Gain a report delineating the decision criteria for superiors or financiers.

- Huge savings! Because of our robotic bag palletizing experience, this contract engineering service costs amazingly little. We typically save the client many times over what we charge.

Let us show you how quickly and affordably robotic bag palletizing can be implemented in your production facility. Please contact us anytime! We look forward to hearing from you.

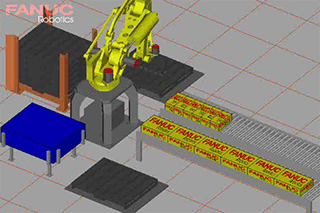

Robotic End-of-Line System Analysis

- Feasibility Studies

- System Methodology Analysis (Dedicated, Load Accumulating, Layer Accumulating, Load Shuttling, Layer Shuttling, Turntable, Row Transfer, Vacuum Pick, Clamp, Fork-Style, Clamshell, Case/Row/Layer Pick,

- Cell Design

- Line Layout Options

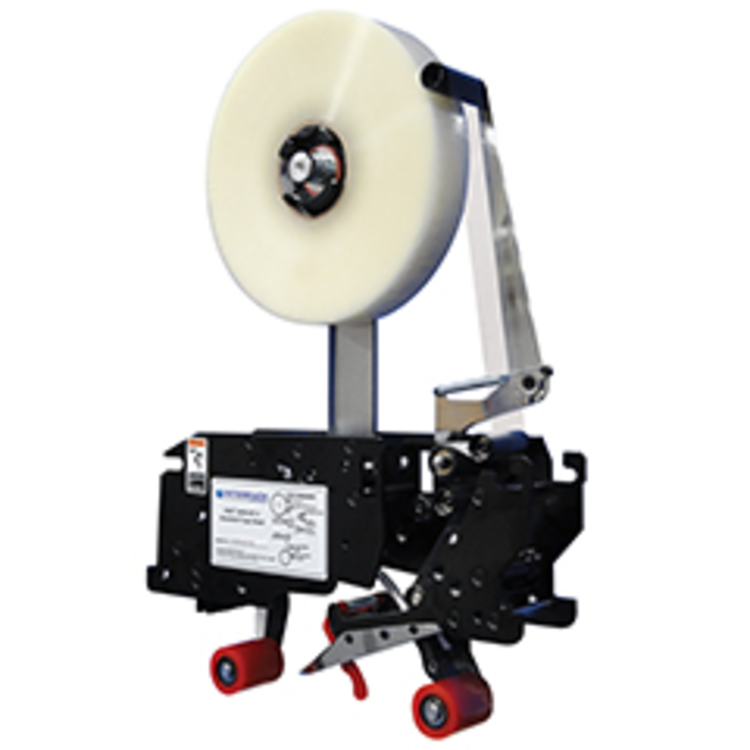

- End-Of-Arm Tooling Design Recommendations

- Rate Studies

- Reach Studies

- Rate Optimization

- Palletizer Simulation

- Accumulation Studies

- Cell Density Optimization

- Compare Contrast Robot Brands relative to your application

- Develop software integration concept

- Contribute to Package Design

- Recommend wash-down / sanitation options

- Specify the correct ancilliary equipment

- Specify integrated upstream and downstream equipment that will enhance, not hinder system performance

- Develop requests for Robotics, case packing and palletizing Quote

- Estimate lead time requirements

- Provide budgetary information for the equipment and services you need

Robotic End-of-Line Project Management

- Perform on-site visit(s) to verify all proposed system solution criteria and address final technical and commercial concerns with a final robotic bag palletizer proposal

- Manage Contractors

- Proofs-of-Concept

- Custom Tooling Design

- Monitor the project schedule

- Ensure that the system quality criteria is met or exceeded

- Ensure safety requirements are met

- Ensure sanitation requirements are met

- Provide a go-to source for service, programming, parts and system modifications

- Follow-up on warranty issues, if any

- Approve FAT's

- Coordinate Installation

- Manage Start-Up

- Certify and Approve Training

- Work to exceed customer expectation

- Provide information on system expandability